PRINTING BLANKETS

BDprint - setting new standards in textile printing.

BDprint.

Screen Printing Blankets from DAISLER

In early 2013, the DAISLER team came together and focused its efforts on developing a revolutionary product for the textile printing industry. The result of countless hours between the R&D facilities and our engineers in Germany is a mere perfect product that has immediately proven to create wonderful printing results in the most challenging environments at our clients.

The name is BDprint. The widest belt in the industry!

Our BDprint screen printing blankets have been designed to meet the demands of the textile printing industry around the world. They are ideal for very long printing tables that require a high tensile strength and great preciseness, short printing machineries that have high demands on printing speed and everything in between.

BDprint is suitable for:

-

Rotary Printing

-

Scrapper

-

Magnectic bar

-

-

Flatbed Printing

-

Scrapper

-

Magnectic bar

-

-

Digital Printing

-

Ceramic Tile Printing

APPLICATIONS

We at DAISLER guarantee the perfect surface and uniform thickness of our printing blankets, which are controlled by fully automatic measuring devices. Furthermore, the usage of specially developed high solvent resistant TPU material from Germany means that BDprint screen printing blankets have one of the most durable surfaces in the industry and allow the usage of all common cleaning agents. Strength and accuracy go hand in hand in textile printing. That’s the reason why we have comeup with unique fabric constructions of polyester and Kevlar that result in extremely strong and precise belts.

-

Perfect surface and uniform thickness

-

Highly abrasion & chemical resistant TPU surface

-

Unique fabric constructions, ease of adjustment at installation

-

High tensile strength

-

Excellent tracking

CHARACTERISTICS

There are several types of BDprint screen printing blankets available, the two most popular ones are BD20T & BD65K.

BD20TT specifications:

-

2.6mm thickness

-

20N/mm tensile force for 1.0% elongation

-

2 plies polyester fabric

-

Production width: 3,800mm

BD30KT specifications:

-

2.6mm thickness

-

30N/mm tensile force for 1.0% elongation

-

2 plies polyester fabric, 1 ply Aramid (ETK) fabric

-

Production width: 3,800mm

BD65K specifications:

-

2.6mm thickness

-

65N/mm tensile force for 1.0% elongation

-

2 plies polyester, 1 ply Aramid (EMK) fabric

-

Production width: 3,800mm

SPECIFICATIONS

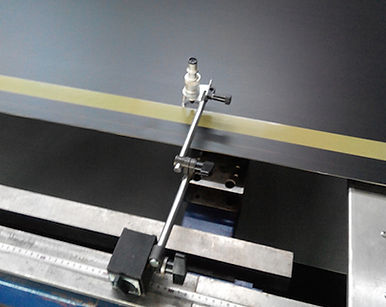

DAISLER has mastered the art of installation of our BDprint printing blankets and more than 250 belts have been successfully jointed and installed. We are happy to provide you with either pre-jointed belts according to the required dimensions or with belts prepared for jointing on site. Our team will provide specific information for joining instructions and a special training manual to ensure your success at achieving a perfect and seamless result.

-

BDprint installed on 250+ machines

-

35,000+ sqm of running printing machines

-

Under operation on most popular machine manufacturers

INSTALLATION